- Home

- Products

- About Us

- Services & Support

- News

- Contact Us

Views: 350 Author: Site Editor Publish Time: 2025-11-15 Origin: Site

Content Menu

>> The Imperative for Wastewater Pumping

>> Defining Integrated Wastewater Pumping Stations

>> Key Components of an Integrated System

>>> Wet Well

>>> Internal Pipework and Valves

>>> Control System and Instrumentation

>>> By Construction and Installation

>>> By Application and Flow Rate

>>> By Regulation and Standard (e.g., Water UK's “Sewers for Adoption”)

>> Design Principles and Considerations

>>> Hydraulic Design

>>> Location and Environmental Impact

>>> Electrical and Control Systems

>>> Safety

>>> Preventive and Predictive Maintenance

>>> Cleaning

>>> Troubleshooting Common Issues

>>> Data Monitoring and Analysis

>> Applications of Integrated Wastewater Pumping Stations

>>> Urban and Municipal Infrastructure

>>> Residential and Commercial Developments

>>> Decentralized Wastewater Treatment Systems

>>> Flood Control and Stormwater Management

>>> Operational Efficiency and Reliability

>>> Space Efficiency and Aesthetics

>>> Installation and Flexibility

>> Challenges and Disadvantages

>>> High Initial Capital Cost (for advanced systems)

>>> Power Dependency

>>> Odor and Noise

>> Future Trends and Technologies

>>> Smart and IoT-Enabled Pumps

>>> Artificial Intelligence and Machine Learning

>>> Cloud-Based Platforms and Digital Twins

>>> Enhanced Energy Efficiency

>>> Advanced Solids Handling and Self-Cleaning Features

>>> Modular and Flexible Designs

>> Conclusion

>> Related Questions and Answers

Wastewater management is a critical aspect of modern infrastructure, essential for public health, environmental protection, and sustainable urban development. Integrated wastewater pumping stations represent a significant advancement in this field, offering efficient, reliable, and often more compact solutions compared to traditional pumping systems. These stations are designed to address the challenges of moving wastewater through varied terrains and to higher elevations, ensuring a continuous and uninterrupted flow to treatment facilities.

In many geographical areas, natural gravity flow alone is insufficient to convey wastewater from collection points to treatment plants. Factors such as flat topography, low-lying areas, or the need to cross natural barriers necessitate the use of pumping stations. Traditional wastewater collection systems rely on gravity sewers, which require a continuous downward slope. When this slope cannot be maintained, or when wastewater needs to be lifted to a higher elevation, pumping stations become indispensable. They act as vital links in the wastewater network, transforming potential stagnation points into active transport hubs. Without them, wastewater would accumulate, leading to severe public health risks, environmental contamination, and systemic failures in urban sanitation.

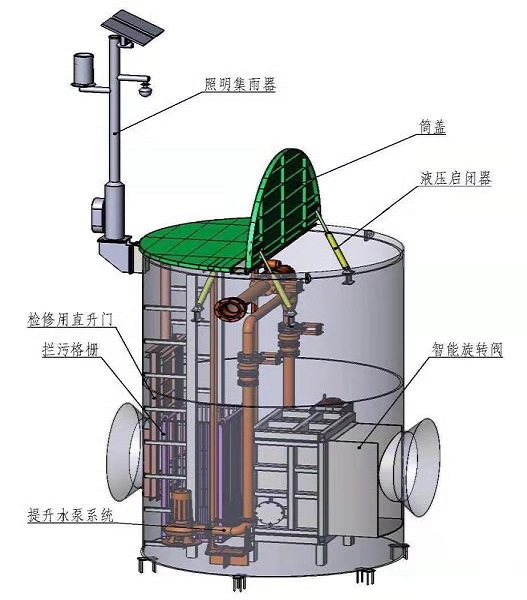

An integrated wastewater pumping station, often referred to as a packaged pumping station or lift station, is a self-contained, modular unit designed for efficient collection and transportation of wastewater. Unlike conventional, site-built pumping stations that involve extensive on-site construction and assembly of disparate components, integrated stations are typically prefabricated. They arrive as a complete system, incorporating the wet well, submersible pumps, internal pipework, valves, control systems, and sometimes even a grinder or macerator, all within a compact, often underground, housing. This modular design significantly streamlines installation and reduces the overall footprint required.

The core principle behind an integrated station is to centralize and optimize all necessary components for wastewater lifting within a single, cohesive unit. This integration leads to improved performance, reduced installation time, and enhanced operational efficiency. These systems are specifically engineered to handle raw sewage, which includes both liquid and solid waste, and are designed for robust, reliable operation under varying flow conditions.

The effective functioning of an integrated wastewater pumping station relies on several interconnected components, each playing a crucial role in the overall system.

The wet well is the primary collection chamber where wastewater accumulates before being pumped. It is designed to store incoming sewage, allowing the pumps to operate in an efficient start-stop cycle. The size and configuration of the wet well are critical for preventing excessive pump cycling and ensuring adequate retention time without allowing the wastewater to become septic. Integrated stations typically feature pre-engineered wet wells made from durable materials like fiberglass, polyethylene, or precast concrete, providing excellent corrosion resistance and structural integrity.

At the heart of any pumping station are the pumps. Integrated stations predominantly utilize submersible pumps, which are designed to operate while fully immersed in the wastewater within the wet well. These pumps are robust, self-cooling, and often equipped with non-clog impellers or cutting mechanisms (grinder pumps) to handle solids effectively, minimizing the risk of blockages. Typically, these stations include at least two pumps for redundancy, operating in a duty/standby configuration to ensure continuous service even if one pump requires maintenance or fails. This redundancy is vital for operational reliability and preventing overflows.

Within the integrated unit, a precisely engineered network of internal pipework directs the flow of wastewater. This includes suction lines from the wet well to the pumps and discharge lines that carry the pumped wastewater away. Non-return valves (check valves) are critical to prevent backflow into the wet well when a pump stops or during power outages. Isolation valves are also included to allow individual pumps or sections of pipework to be isolated for maintenance without disrupting the entire system.

Modern integrated pumping stations feature sophisticated control systems that automate their operation. These typically include a control panel, motor starters, and programmable logic controllers (PLCs). Level sensors (e.g., floats, pressure transducers, or ultrasonic sensors) monitor the wastewater level in the wet well, triggering pumps to start or stop at predetermined levels. Alarm systems provide alerts for high-level conditions, pump failures, power outages, and other critical operational issues. Advanced control systems often incorporate variable frequency drives (VFDs) to optimize pump speed, matching the pumping rate to the inflow, thereby enhancing energy efficiency and reducing wear and tear on the pumps.

Depending on the specific application and site conditions, integrated stations may also include additional components such as:

* Grinders or Macerators: For stations handling particularly challenging waste streams with high solids content, grinders or macerators can be integrated to break down large solids into smaller, more manageable particles before pumping, preventing clogs.

* Ventilation Systems: To manage odors and prevent the buildup of hazardous gases like hydrogen sulfide within the wet well or access chambers.

* Safety Features: Such as access ladders, fall protection, and robust covers for safe inspection and maintenance.

Integrated wastewater pumping stations come in various configurations, often categorized by their application, size, and specific features.

* Submersible (Wet Well) Stations: These are the most common type of integrated station, where the pumps are submerged directly in the wastewater. The entire unit, including the wet well, is typically installed underground. They are compact, relatively quiet, and offer good aesthetic integration into the landscape.

* Dry Well Stations (less common for integrated packages): In traditional dry well stations, pumps are housed in a separate, dry chamber adjacent to the wet well. While offering easier access for maintenance, they require a larger footprint and more complex construction. Integrated solutions often aim to minimize this by using fully submersible components.

* Above-Ground Package Stations: Some integrated systems, particularly for specific industrial or remote applications, might have components mounted above ground, offering easier access and maintenance, but requiring more visible infrastructure.

* Small-Scale/Residential Stations: Designed for individual homes, small commercial properties, or clusters of buildings where gravity drainage is not feasible. These typically handle lower flow rates and may feature single or duplex pumps.

* Municipal/District Stations: Larger capacity stations used within municipal sewage networks to collect wastewater from entire neighborhoods or districts and pump it to larger interceptor sewers or directly to a treatment plant. These require higher flow redundancy and more sophisticated monitoring.

* Industrial Wastewater Stations: Tailored for industrial facilities, these stations must often handle specific types of industrial effluent, which might include corrosive chemicals, higher temperatures, or abrasive solids, requiring specialized pump materials and designs.

* Stormwater Pumping Stations: While this article focuses on wastewater, integrated designs are also used for stormwater management, particularly in low-lying urban areas prone to flooding. These are designed for high intermittent flows.

* Type 1-4 Classifications: In some regions, pumping stations are classified based on incoming flow rate and power rating to ensure they meet specific standards for adoption by local water authorities. Type 1 represents smaller, simpler stations, while Type 4 denotes large, complex, and highly monitored systems.

The design of an integrated wastewater pumping station is a complex engineering task that must balance efficiency, reliability, maintainability, and environmental considerations.

Proper hydraulic design is paramount. This involves accurately determining the expected wastewater inflow rates (minimum, average, and peak flows), calculating the total dynamic head (TDH) required to lift the wastewater to the discharge point, and selecting pumps that can efficiently operate across this range of conditions. The piping within the station and the connected force main must be sized to maintain adequate flow velocities to prevent solids from settling and minimize friction losses. Consideration must also be given to transient analysis (water hammer) to prevent damage to the system.

Pumping stations must be designed with sufficient capacity to handle peak flow events, including those influenced by rainfall-induced infiltration and inflow (I&I) into the sewer system. Redundancy is a critical design principle; typically, at least two pumps are installed so that if one pump fails or is taken offline for maintenance, the remaining pumps can still handle the design flow. For critical applications, three or more pumps might be used, providing "N+1" or "N+2" redundancy.

The physical location of a pumping station requires careful consideration. It should be placed as far as practically possible from residential areas to mitigate noise and odor nuisances. Buffer zones, landscaping, and appropriate architectural design can help integrate the station into its surroundings. Furthermore, the design must prevent any potential contamination of potable water supplies and protect groundwater resources. Measures for odor control, such as activated carbon filters or chemical dosing, are often necessary.

The electrical system must be robust and reliable, providing consistent power to the pumps and control equipment. This includes motor control centers, protective relays, and emergency power provisions (e.g., backup generators or redundant power feeds) to ensure continued operation during power outages. Modern control systems integrate SCADA (Supervisory Control and Data Acquisition) for remote monitoring, data logging, and automated control, allowing operators to manage the station efficiently from a central location.

Given the corrosive and abrasive nature of wastewater, material selection for all components is crucial. Stainless steel, corrosion-resistant coatings, and durable plastics are commonly used for pumps, pipes, valves, and wet well structures to ensure longevity and minimize maintenance.

Safety for personnel involved in operation and maintenance is a non-negotiable design consideration. This includes providing safe access to all components, proper ventilation to prevent hazardous gas accumulation, and adherence to confined space entry regulations where applicable. The integrated nature of many modern stations aims to reduce direct human interaction with raw sewage.

Effective operation and maintenance (O&M) are essential for the longevity, efficiency, and reliability of integrated wastewater pumping stations. A well-structured O&M program can prevent costly breakdowns, minimize environmental impacts, and extend the lifespan of the equipment.

Regular visual inspections are fundamental. Operators should check for obvious signs of wear, leaks, unusual noises, odors, and proper functioning of alarms and indicators. Wet wells should be inspected for debris buildup and cleanliness. Critical stations may require inspections multiple times per week, while less critical ones might be inspected weekly or bi-weekly.

A preventive maintenance schedule involves planned tasks such as lubricating moving parts, checking electrical connections, testing control panels, and calibrating sensors. Predictive maintenance utilizes monitoring data (e.g., pump vibration, motor temperature, power consumption) to anticipate potential equipment failures before they occur, allowing for scheduled repairs and replacements, thereby minimizing unplanned downtime. Modern integrated stations with advanced sensors and SCADA systems facilitate predictive maintenance strategies.

Regular cleaning of the wet well is crucial to prevent the accumulation of rags, grit, and other debris that can clog pumps and sensors, lead to septicity, and generate odors. Cleaning frequency depends on the characteristics of the incoming wastewater and can range from semi-annual to more frequent intervals.

Despite diligent maintenance, issues can arise. Common problems include pump clogging, motor failures, electrical malfunctions, control system errors, and excessive noise or vibration. Operators need training to diagnose these issues promptly and either resolve them or escalate them to specialized technicians.

Advanced integrated stations often incorporate sophisticated monitoring systems that collect real-time data on flow rates, pump run times, power consumption, wet well levels, and alarm statuses. Analyzing this data helps optimize pump operation, identify trends, predict maintenance needs, and assess overall system performance. Remote monitoring capabilities allow operators to oversee multiple stations from a central control room, improving response times to critical events.

Integrated wastewater pumping stations are highly versatile and find application across a broad spectrum of settings due to their efficiency and adaptability.

In rapidly urbanizing areas, these stations are vital for extending sewer networks to new developments or areas where gravity sewers are impractical. They manage the flow of domestic and commercial wastewater, ensuring it reaches centralized treatment plants without disruption. They are particularly useful in flat terrains or in systems that need to cross geographical depressions or rivers.

Individual homes, housing estates, commercial complexes, and industrial parks often require dedicated pumping stations to lift wastewater from basements or low-lying areas to the municipal sewer system. Integrated package stations are ideal for these applications due to their compact size and ease of installation.

Industries generate various types of wastewater, and integrated pumping stations can be customized to handle these specific effluents. This might include wastewater with particular chemical compositions, high temperatures, or abrasive solids, requiring specialized pump materials and control logic.

In rural areas or locations where connection to a central sewer system is not feasible, integrated pumping stations can be part of decentralized wastewater treatment solutions, moving sewage from collection points to smaller, localized treatment facilities.

While distinct from wastewater, the underlying technology of integrated pumping stations is also employed in stormwater management to prevent flooding in low-lying urban areas by rapidly pumping accumulated rainwater into drainage systems or larger waterways.

Integrated wastewater pumping stations offer numerous benefits over traditional, on-site constructed systems, contributing to more efficient and sustainable wastewater management.

* Reduced Construction Costs: Prefabrication and modular design significantly cut down on civil engineering works, labor, and on-site construction time, leading to lower overall project costs.

* Lower Operational Costs: Intelligent control systems and energy-efficient pumps, often equipped with VFDs, can reduce energy consumption by optimizing pump operation based on real-time flow demands.

* Reduced Maintenance: High-quality components, non-clog designs, and remote monitoring capabilities can lead to fewer breakdowns and lower maintenance labor requirements.

* Pollution Prevention: Reliable pumping ensures continuous wastewater flow, preventing sanitary sewer overflows (SSOs) that can contaminate natural water bodies, harm ecosystems, and pose public health risks.

* Odor Control: Integrated systems can incorporate effective odor control measures, improving air quality in the vicinity of the station.

* Protection of Groundwater: By effectively collecting and transporting wastewater, these stations help prevent the infiltration of untreated sewage into groundwater resources.

* Enhanced Reliability: Redundant pump configurations and robust components ensure continuous operation, even during peak flow periods or in the event of component failure.

* Automated Operation: Advanced control systems minimize the need for manual intervention, allowing for remote monitoring and control, and providing immediate alerts for anomalies.

* Predictive Maintenance: Data analytics from integrated control systems enable proactive maintenance, reducing unexpected failures and extending equipment lifespan.

* Small Footprint: Their compact, often underground design requires minimal surface area, making them suitable for urban environments where space is limited.

* Aesthetic Integration: With minimal visible structures, integrated stations can be easily integrated into the landscape without causing visual blight.

* Rapid Installation: Prefabricated units can be installed much faster than traditional stations, reducing project timelines and disruption.

* Adaptability: Modular designs allow for customization to suit specific site conditions, flow requirements, and future expansion needs.

Despite their many advantages, integrated wastewater pumping stations also present certain challenges and potential disadvantages that need to be carefully managed.

While offering long-term savings, the initial capital investment for a highly integrated, technologically advanced pumping station can be substantial, particularly for systems incorporating smart technologies and robust redundancy. This can be a barrier for smaller municipalities or private developers with limited budgets.

The reliance on sophisticated control systems, sensors, and communication networks means that failures in these technological components can disrupt operations. Cybersecurity risks also become a consideration for networked systems.

While overall maintenance might be reduced, the specialized nature of integrated components, particularly advanced electronics and automation, requires skilled technicians for troubleshooting and repair. This can necessitate specialized training or reliance on external service providers.

Although modern designs aim to minimize human entry into wet wells, maintenance tasks may still occasionally require confined space entry, posing safety risks due to hazardous gases and potential drowning hazards. Strict safety protocols and equipment are essential.

All pumping stations rely on a continuous power supply. While backup generators or redundant power sources mitigate this, prolonged power outages without adequate backup can lead to system failure and overflows.

Despite design efforts, pumping stations can still be sources of odor, especially if the wet well becomes septic or if ventilation systems fail. Noise from pumps, particularly in above-ground installations, can also be a concern in sensitive locations.

Despite non-clog pump designs and grinders, wastewater streams can contain significant amounts of debris (e.g., wipes, plastics) that can still cause blockages, especially in stations not adequately screened or with insufficient solids-handling capacity.

The field of integrated wastewater pumping stations is continuously evolving, driven by advancements in technology, increasing environmental regulations, and the growing demand for sustainable urban infrastructure.

The future will see widespread adoption of smart, IoT-enabled pumps that offer real-time monitoring, remote diagnostics, and predictive maintenance capabilities. These pumps will communicate wirelessly, providing operators with immediate insights into performance, energy consumption, and potential issues, allowing for proactive interventions.

AI and machine learning algorithms will play an increasingly crucial role in optimizing pump operations. These systems can analyze historical data, predict flow patterns, and adjust pump speeds and cycling to maximize energy efficiency, minimize wear, and prevent overflows. AI-driven systems may also identify anomalies that indicate impending failures, enabling predictive maintenance to a much higher degree.

Cloud-based platforms will facilitate remote monitoring, data analysis, and overall management of entire networks of pumping stations. The concept of "digital twins" – virtual replicas of physical assets – will allow engineers and operators to simulate various operational scenarios, test upgrades, and optimize performance in a virtual environment before implementing changes in the physical world.

The drive for sustainability will continue to push innovations in energy-efficient pump designs and control strategies. Variable frequency drives (VFDs) will become standard, and new motor technologies will further reduce power consumption. The integration of renewable energy sources, such as solar power, to offset grid electricity consumption, particularly in remote or off-grid locations, is also an emerging trend.

To combat persistent clogging issues, future pumps will feature even more advanced solids-handling capabilities, potentially with self-cleaning impellers or automated backflush systems. Innovations in cutter pumps and macerators will enhance their ability to process challenging waste streams, reducing maintenance downtime.

Integrated pumping stations will become even more modular and adaptable, allowing for easier upgrades, expansions, and relocation if needed. This flexibility will be crucial for rapidly evolving urban landscapes and changing wastewater demands.

The long-term vision includes autonomous pumping stations capable of self-diagnosis, self-optimization, and even minor self-repairs. While full autonomy is still some way off, significant steps towards self-regulating systems are expected, further reducing the need for human intervention and improving operational resilience.

Integrated wastewater pumping stations are indispensable components of modern wastewater management systems, providing essential infrastructure for collecting and conveying sewage in diverse geographical and urban settings. Their prefabricated, modular design offers substantial advantages in terms of cost-effectiveness, rapid installation, space efficiency, and environmental protection. By consolidating pumps, controls, and associated equipment into a single unit, these stations enhance operational efficiency and reliability, contributing significantly to public health and environmental sustainability. While challenges such as initial investment and the need for specialized maintenance exist, ongoing technological advancements in smart systems, AI, and energy efficiency are continuously refining these solutions. The future of integrated wastewater pumping stations promises even greater automation, intelligence, and sustainability, ensuring that communities can effectively manage their wastewater infrastructure for generations to come.

1. What is the primary function of a wet well in an integrated wastewater pumping station?

The primary function of a wet well is to collect and store incoming wastewater before it is pumped. It allows the pumps to operate in a start-stop cycle, preventing them from running too frequently (short-cycling) or too infrequently, which can lead to inefficient operation or septicity in the wastewater.

2. Why is redundancy important in the design of integrated wastewater pumping stations?

Redundancy, typically achieved by installing multiple pumps (e.g., duty/standby configuration), is crucial to ensure continuous operation and reliability. If one pump fails or requires maintenance, the other(s) can take over, preventing interruptions in wastewater conveyance, system overflows, and potential environmental or public health hazards.

3. What are some key environmental benefits of using integrated wastewater pumping stations?

Key environmental benefits include preventing sanitary sewer overflows (SSOs) that can contaminate natural water bodies and harm ecosystems, minimizing odors through controlled ventilation and optimized pump cycling, and protecting groundwater resources from untreated sewage infiltration.

4. How do smart technologies and IoT enhance the operation of these pumping stations?

Smart technologies and IoT enhance operation by enabling real-time monitoring of pump performance, flow rates, and wet well levels. This data allows for remote control, predictive maintenance (anticipating failures before they occur), optimized energy consumption through adaptive pump control, and quicker response to alarms or anomalies, ultimately increasing efficiency and reliability.

5. What are the main challenges associated with the long-term maintenance of integrated wastewater pumping stations?