- Home

- Products

- About Us

- Services & Support

- News

- Contact Us

loading

●No air compressor or pressure vessel required

● Saves on operating costs and floor space, and reduces investment.

● Simple, compact, and maintenance-free

●Industrial wastewater pretreatment and end-of-pipe treatment

● Oily wastewater treatment

● Upgrading of municipal water plants

● Oily wastewater treatment in the petrochemical processing industry

● Oily wastewater and reinjection water from oil extraction industry

● Wastewater treatment in the meat processing industry

● Wastewater treatment in the dairy processing industry

●White water treatment in pulp and paper manufacturing

● Oily wastewater treatment in the machinery processing industry

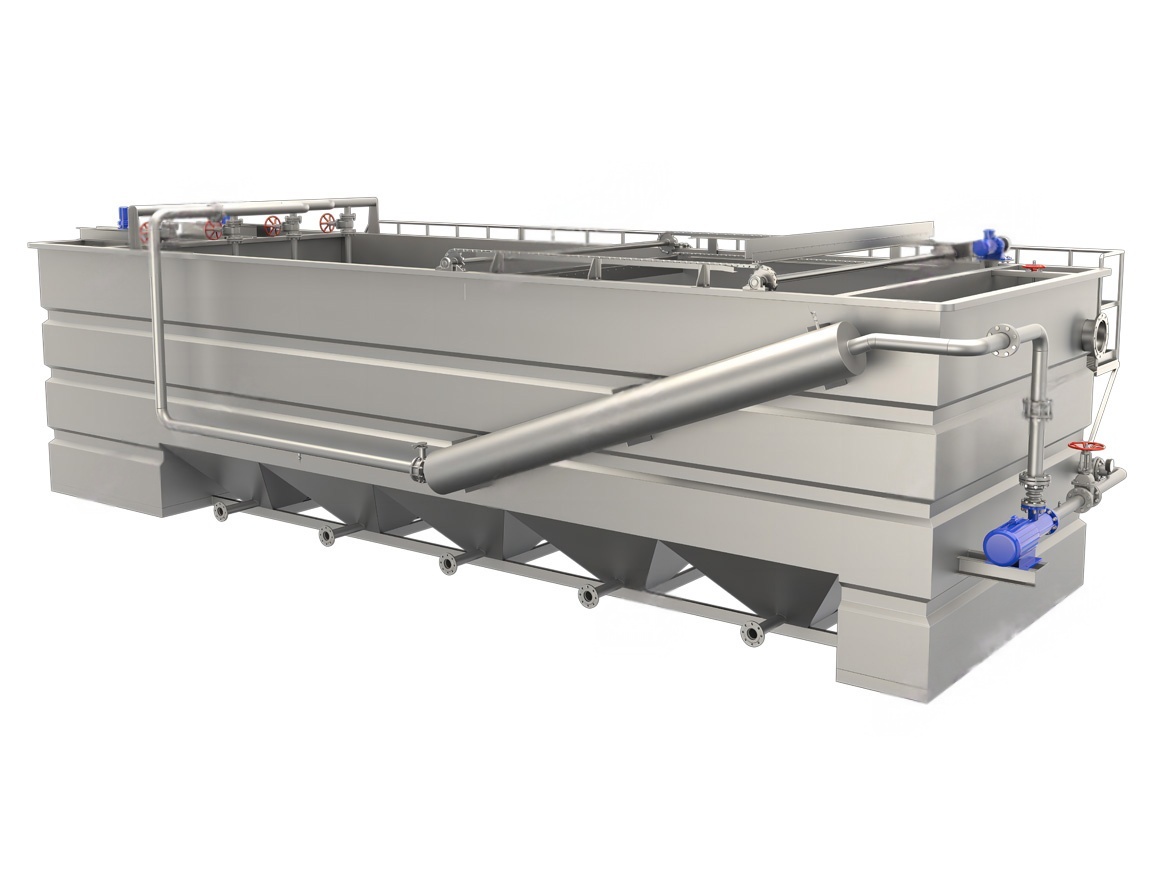

The performance of multiphase miscible air flotation mainly depends on the gas content in the multiphase mixed solution. When the pump draws in liquid, a certain negative pressure is formed at the pump inlet, and air is drawn in along with the liquid through the suction port. After being sheared by the high-speed rotating pump impeller, the gas dissolves in the liquid. By adjusting the operating point and the gas-liquid mixing ratio, highly dispersed microbubbles or the maximum gas entrainment requirement can be obtained.

Depending on the pump specifications, the gas content in the liquid can reach 30%. When this saturated (or even supersaturated) dissolved gas water enters the dissolved gas tank, after a certain period of stabilization, it is released by the release device through instantaneous decompression, releasing highly dense microbubbles with an average particle size of less than 30 μm.

Finally, the flocculated wastewater enters the flotation tank and mixes with these microbubbles. The microbubbles attach to the suspended solids and carry them to the water surface. Once at the surface, the suspended solids are supported by these bubbles and held on the surface. The scum formed on the surface is then scraped into the scum trough by a scum scraper.

Model number | ( Processing capacity (m³/h) m³/h) | Dimensions L×B×H (m) B×H (m) | Multiphase flow pump (kW) Pump (kW) | Slag scraper (kW) (kW) | Total power (kW) Power (kW) |

GDXF-3 | 3 | 2.5 × 0.8 × 1.9 | 1.1 | 0.2 | 1.3 |

GDXF-5 | 5 | 3.0 × 1.0 × 1.9 | 1.1 | 0.2 | 1.3 |

GDXF-10 | 10 | 4.0×1.2×2.1 | 2.2 | 0.2 | 2.4 |

GDXF-15 | 15 | 4.5×1.5×2.1 | 3 | 0.4 | 3.4 |

GDXF-20 | 20 | 4.5×1.8×2.1 | 3 | 0.4 | 3.4 |

GDXF-30 | 30 | 5.5×2.0×2.1 | 4 | 0.4 | 4.4 |

GDXF-40 | 40 | 6×2.2×2.1 | 4 | 0.4 | 4.4 |

GDXF-50 | 50 | 6×2.7×2.1 | 4 | 0.4 | 4.4 |

GDXF-60 | 60 | 7×2.8×2.1 | 5.5 | 0.4 | 5.9 |

GDXF-70 | 70 | 8×3.0×2.1 | 5.5 | 0.4 | 5.9 |

GDXF-80 | 80 | 9×3.2×2.1 | 11 | 0.4 | 11.4 |

GDXF-100 | 100 | 9×3.6×2.1 | 15 | 0.4 | 15.4 |