- Home

- Products

- About Us

- Services & Support

- News

- Contact Us

loading

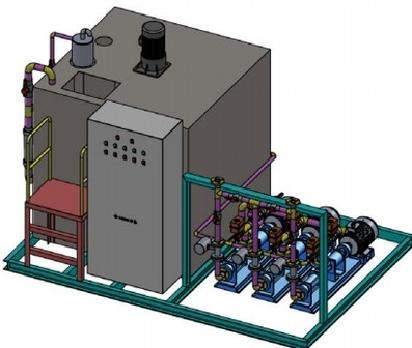

The dry powder preparation and dosing device uses granular, powdered, or concentrated liquids such as flocculants, potassium permanganate, and activated carbon as raw materials to continuously and automatically prepare powders at the required concentration. The prepared solution is then continuously metered and added to the industrial process.

Features:

Features:

• Highly integrated and highly automated, the system can achieve intelligent control.

• Highly integrated and highly automated, the system can achieve intelligent control.

The equipment is small in size, simple to operate, and easy to install. On-site installation only requires connecting to a water source and a power source.

The equipment is small in size, simple to operate, and easy to install. On-site installation only requires connecting to a water source and a power source.

• The system is safe and reliable in operation. In case of failure, the system will automatically shut down and issue an alarm signal.

• The system is safe and reliable in operation. In case of failure, the system will automatically shut down and issue an alarm signal.

automatically adjust the dry powder dosage according to changes in water flow .

• It has good corrosion resistance, and all parts in contact with the medium are made of engineering plastics and stainless steel.

• It has good corrosion resistance, and all parts in contact with the medium are made of engineering plastics and stainless steel.

It is suitable for the preparation and addition of powdery, granular, and fibrous materials .

Application areas: Widely used in water treatment, wastewater treatment, and other process media treatment in industries such as petroleum, chemical, papermaking, power, coal, pharmaceutical, and food.

Data parameters

Specifications and Models | Configuration parameters | Control method | |||

Volume (L) | Pump and tank configuration | Material | External dimensions L×W×H (mm) | ||

CT□-1□□/10□ |

30-20000 | 1 barrel 1 pump |

304, PE, Carbon steel, rubber-lined steel UPVC | Minimum: 350×350×400 Maximum: 3150×3150×3350 | Manual button/automatic instrument control /PLC Touch Control/DCS Remote Control /GPRS wireless/Special requirements Seeking (explosion-proof, frequency conversion, etc.) Power supply: 220V/380V 50Hz |

CTD-1□□/2□□ | 1 barrel 2 pumps | Minimum: 350×350×400 Maximum: 3150×3150×3350 | |||

CTO-2□□/1□□ | 2 barrels and 1 pump | Minimum: 700×500×400 Maximum: 6900×3500×3350 | |||

CTD-2□□/2□□ | 2 barrels 2 pumps | Minimum: 700×500×400 Maximum: 6900×3500×3350 | |||

CTD-2□□/3□□ | 2 barrels 3 pumps | Minimum: 700×500×400 Maximum: 6900×3500×3350 | |||