- Home

- Products

- About Us

- Services & Support

- News

- Contact Us

loading

DM DIGITAL METERING PUMP

SUMMARY

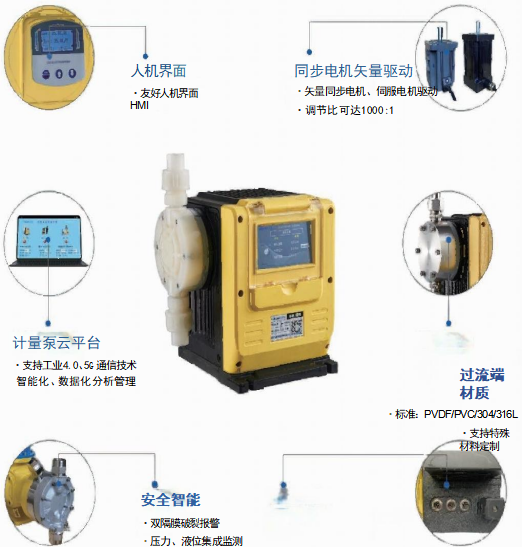

To address the trends of automation and intelligentization, Ligo Pumps, drawing on years of experience in positive displacement pump applications, has developed its own intelligent digital metering pump, providing customers with intelligent solutions for precise chemical dosing. This digital metering pump innovatively employs stepper motor vector drive and an advanced MCU... The microcontroller unit and software program are customized and optimized to achieve accurate metering and dosing over a wide range. The digital metering pump features a simple mechanical structure , convenient installation and maintenance, and integrates multiple intelligent designs. It offers manual/automatic and remote/local modes, and monitors and controls flow, level, pressure, time, and safety alarms. The system is automated through an integrated microprocessor for computation and feedback, and supports Modbus RTU. The communication protocol enables bidirectional communication, and it features a user-friendly human-machine interface system (HMI/LCD). Make the operation more convenient .

TECHNICAL PARAMETER

1. Flow range: Mechanical diaphragm type Qmax=6000L/H, plunger and hydraulic diaphragm type Qmax=21m³/h

2. Pressure range: Mechanical diaphragm type Pmax=1.2Mpa, Piston, hydraulic diaphragm type Pmax=70Mpa

3. Electrical parameters: AC220/380V, Single-phase/three-phase, 50/60 Hz Optional explosion protection rating

4. Flow-through end materials: PVC, PVDF, 304/316L, 904, 2205, Ti, Hastelloy C , etc.

5. Optional configurations: Integrated monitoring and control of pressure and liquid level, dual diaphragm safety protection, etc.

DMIJM DM/JM SERI ES OVERVIEW

DM Series: HMI ( Human Machine Interface) that can integrate modules such as pressure, level, and time, offering a high degree of automation.

JM series: LCD + buttons, simple operation, suitable for explosion-proof environments, and has a wide range of applications.

FEATURES

1. Innovation drives superior structural performance, ensuring precision and reliability.

2. Metering accuracy ±1, flow rate adjustment ratio 1000:1

3. Modular design, suitable for diaphragm, plunger, and hydraulic diaphragm pumps.

4. Modular design, suitable for explosion-proof applications.

5. Supports pressure and level control, and diaphragm rupture alarm.

6. Supports timed, quantitative, and cyclical batch dosing.

7. Pulse and analog signal control, Modbus RTU bidirectional communication

8. Human-Machine Interface: Touchscreen HMI / Backlit High-Definition LCD

DIGITAL METERING PUMP

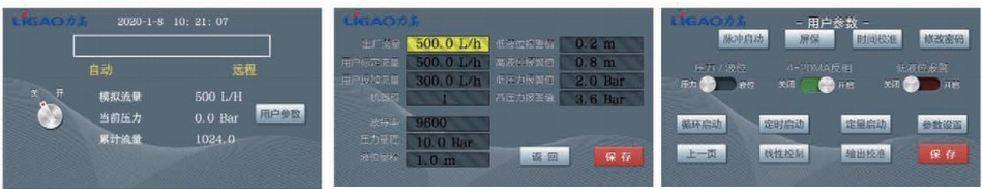

TYPICAL INTERFACE