- Home

- Products

- About Us

- Services & Support

- News

- Contact Us

loading

Process Principle

Calcium and magnesium hardness in boiler feedwater can undergo chemical reactions or crystallize at high temperatures, forming insoluble scale that adheres firmly to the boiler's heating surfaces. This scale is a poor conductor of heat, hindering heat transfer and potentially causing boiler tube rupture in severe cases. Furthermore, it can induce and exacerbate chemical corrosion of under-scale metals, posing a significant hazard. Although boiler condensate and feedwater undergo rigorous softening and desalination treatment, small amounts of calcium and magnesium hardness still enter the boiler water. If this hardness is not treated, it can also form scale, threatening the safe operation of the boiler. Currently, adding phosphate to the boiler water is the most suitable treatment method, with the reaction as follows:

10Ca²⁺ + 6PO₂ + 2OH⁻ → Ca₁(OH)₂(PO₄)₆ (basic calcium phosphate)

Basic calcium phosphate is a soft water sludge that is easily discharged with boiler blowdown and will not adhere to the inside of the boiler to form scale.

Process Overview

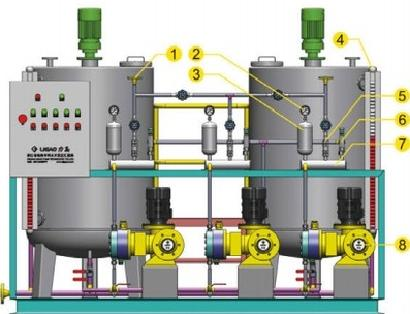

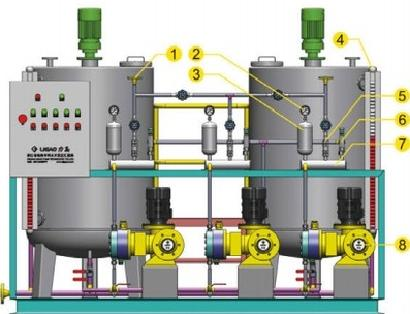

This device mainly consists of four parts: a drug solution preparation system, a metering and dosing system, a safety system, and a control system.

Solid phosphate is added to the dissolving tank, and then demineralized water or condensate is added in proportion and stirred to dissolve. The solution is then added to the boiler drum by the metering and dosing system. Dosing control can be manual or automatic, based on control signals output from the upper-level system.

Application areas

High-pressure and higher parameter steam drum boiler water treatment

Data parameters

Specifications and Models | Configuration parameters | Control method | |||

Volume (L) | Pump and tank configuration | Material | External dimensions L×W×H (mm) | ||

CTD-1□□/1□□ |

30-20000 | 1 barrel 1 pump |

304, PP, PE Carbon steel, rubber-lined steel UPVC | Minimum: 350×350×400 Maximum: 5650×2150×2300 | Manual button/automatic instrument control /PLC Touch Control/DCS Remote Control /GPRS wireless/Special requirements Seeking (explosion-proof, frequency conversion, (Heating and heat preservation, etc.) Power supply: 220V/380V 50Hz |

CTO-1□□/2□□ | 1 barrel 2 pumps | Minimum: 350×350×400 Maximum: 5650×2150×2300 | |||

CTD-2□□/1□□ | 2 barrels and 1 pump | Minimum: 700×500×400 Maximum: 5650×4500×2300 | |||

CTO-2□□/2□□ | 2 barrels 2 pumps | Maximum: 5650×4500×2300 | |||

CTO-2□□/3□□ | 2 barrels 3 pumps | Minimum: 700×500×400 Maximum: 5650×4500×2300 | |||