- Home

- Products

- About Us

- Services & Support

- News

- Contact Us

loading

Coal mines are major water consumers, using water extensively for production, heating, fire fighting, bathing, coal washing, and coking, and are also major sources of wastewater. Using municipal water supply systems would not only increase water consumption but also waste significant resources. Since many water-using applications have relatively lenient water quality requirements, treated mine produced water can easily meet their standards. Therefore, establishing a mine produced water reuse system not only opens up a second water source, reduces fresh water intake, decreases wastewater discharge, and mitigates pollution of receiving water bodies, but also reduces investment in environmental pollution control. Thus, mine produced water reuse saves water resources and eliminates environmental pollution, offering multiple benefits. Mine produced water reuse realizes wastewater resource utilization and is currently the most effective way to solve the two major problems of water conservation and pollution control in coal mines. Treating mine produced water to a level suitable for miscellaneous use requires an infrastructure investment equivalent to drawing water from 30 kilometers away; treating it to a level suitable for reuse as high-requirement process water requires an infrastructure investment equivalent to drawing water from 40-60 kilometers away.

Features

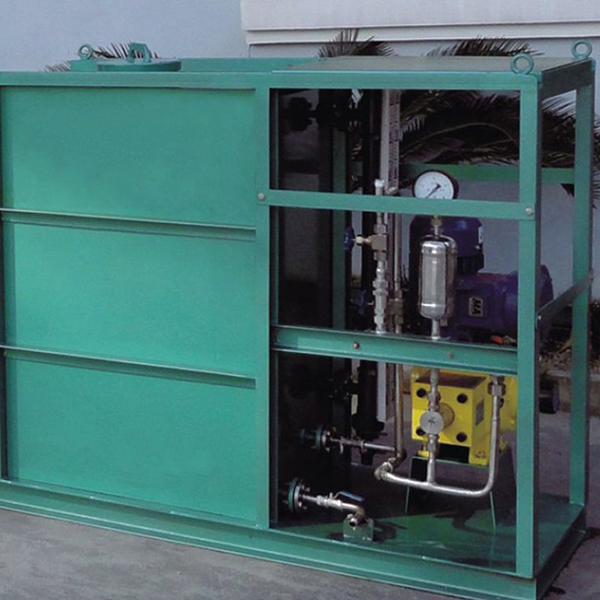

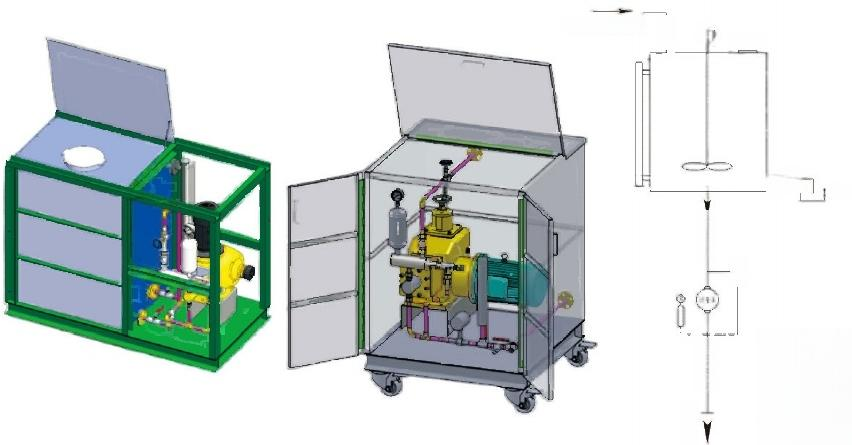

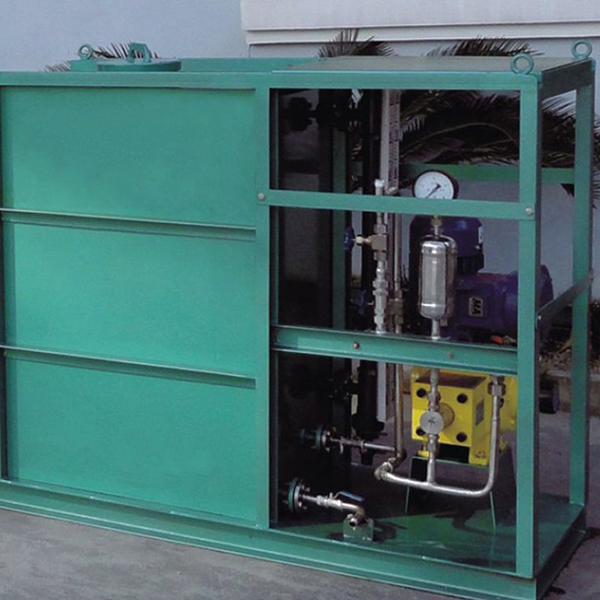

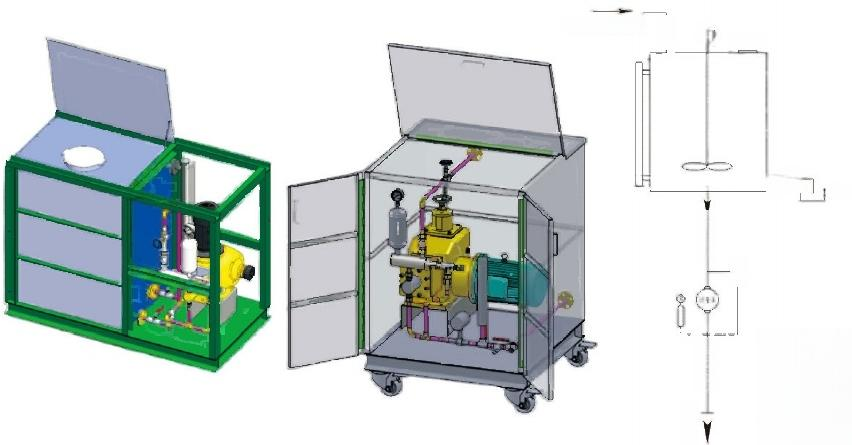

(1) The equipment adopts a fully enclosed/semi-enclosed structure, which can operate stably for a long time under harsh conditions;

(2) The equipment has outstanding advantages such as high temperature resistance, resistance to microbial erosion, high mechanical strength, and stable pore size distribution;

(3) The equipment occupies a small area, saves factory space, is reliable in operation, simple in management, has high filtration accuracy, large treatment capacity, and stable water quality.

(4) The initial investment in equipment is low, and the operating costs are also low;

(5) The equipment is simple and easy to operate, run and maintain.

Application areas: petrochemical industry, mine water treatment engineering

Data parameters

Specifications and Models | Configuration parameters | Control method | |||

Volume (L) | Pump and tank configuration | Material | External dimensions L×W×H (mm) | ||

CTO-1□□/1□□ | 30-20000 | 1 barrel 1 pump | 304, PP, PE Carbon steel, rubber-lined steel UPVC | Minimum: 350×350×400 Maximum: 3150×3150×3350 | Manual button/automatic instrument control /PLC Touch Control/DCS Remote Control /GPRS wireless/Special requirements Seeking (explosion-proof, frequency conversion, etc.) Power supply: 220V/380V 50Hz |

CTD-1□□/2□□ | 1 barrel 2 pumps | Minimum: 350×350×400 Maximum: 3150×3150×3350 | |||

CTD-2□□/1□□ | 2 barrels and 1 pump | Maximum: 6900×3500×3350 | |||

CTO-2□□/2□□ | 2 barrels 2 pumps | Minimum: 700×500×400 Maximum: 6900×3500×2250 | |||

CTD-2□□/3□□ | 2 barrels 3 pumps | Minimum: 700×500×400 Maximum: 6900×3500×3350 | |||