- Home

- Products

- About Us

- Services & Support

- News

- Contact Us

Equipment Introduction

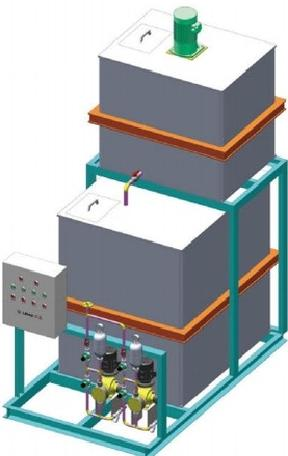

The top-and-bottom structure dosing system is a complete set of equipment integrating dosing, stirring and dissolving, mixing and diluting, storing the solution, conveying fluids, and automatic monitoring and control. It is widely used in various dosing systems and wastewater treatment systems in power plant raw water, boiler feedwater, oilfield surface dehydration treatment, petrochemicals, and other fields. It can douse coagulants, phosphates, ammonia, lime water, water stabilizers, scale inhibitors, bactericides, etc. The upper dissolving and stirring tank serves as the functional unit for dissolving powders, diluting and mixing chemicals, and is connected to the lower storage tank via a ball valve or electric valve. This effectively controls the uniformity of the solution concentration and prevents impurities and waste from being introduced into the dosing system. This ensures the effectiveness and reliability of the system .

Process Overview

This device mainly includes a drug solution preparation system, a metering and dosing system, a safety system, and a control system.

Solid reagents are added to a dissolving tank, then industrial water is added in proportion and stirred to dissolve. The reagent is then added by a metering and dosing system. Dosing control can be manual or automatic, based on control signals from a higher-level system .

Application areas: petrochemical industry, industrial water treatment, wastewater and circulating water treatment

Data parameters

Data parameters

Specifications and Models | Configuration parameters | Control method | |||

Volume (L) | Pump and tank configuration | Material | External dimensions L×W×H (mm) | ||

CTD-1□□/1□□ |

30-20000 | 1 barrel 1 pump |

304, PP, PE Carbon steel, rubber-lined steel UPVC | Minimum: 350×350×400 Maximum: 3150×3150×3350 | Manual button/automatic instrument control /PLC Touch Control/DCS Remote Control /GPRS wireless/Special requirements Seeking (explosion-proof, frequency conversion, etc.) Power supply: 220V/380V 50Hz |

CTD-1□□/2□□ | 1 barrel 2 pumps | Minimum: 350×350×400 Maximum: 3150×3150×3350 | |||

CTD-2□□/1□□ | 2 barrels and 1 pump | Minimum: 700×500×400 Maximum: 6900×3500×3350 | |||

CTO-2□□/2□□ | 2 barrels 2 pumps | Minimum: 700×500×400 Maximum: 6900×3500×3350 | |||

CTD-2□□/3□□ | 2 barrels 3 pumps | Minimum: 700×500×400 Maximum: 6900×3500×3350 | |||