- Home

- Products

- About Us

- Services & Support

- News

- Contact Us

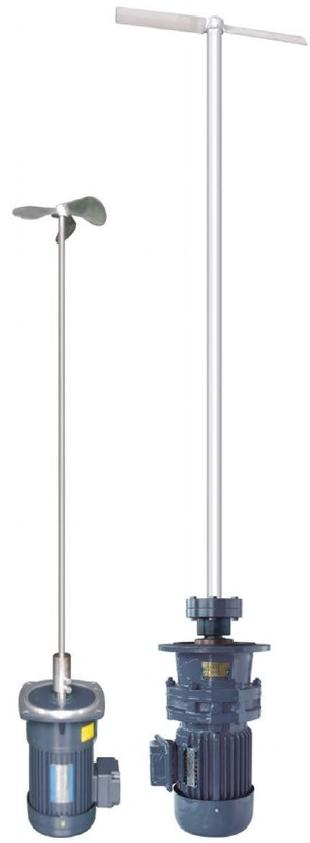

mixing equipment

Product Introduction

Suitable for mixing liquids and solids, and liquids with liquids, with a dynamic viscosity below 30 Pa ·s. It has a simple construction. Easy to install, economical, and the reducer outputs speeds from 16 to 160 rpm . Widely used in chemical, pharmaceutical , and food industries Liquid mixing in industries such as pharmaceuticals, printing and dyeing, and water treatment. The impeller and shaft are made of high-strength, corrosion-resistant 316 and 304 stainless steel. Stainless steel or carbon steel, or custom-made according to customer needs.

Features

Operating environment: Atmospheric pressure, medium temperature 90 ( VRG )-100 ( VRG )

Motor characteristics: 230/400 V, 50 Hz 3 pH

Protection rating: IP55

Structural materials: SUS 316, SUS 304

Driver component: PAL1018PU noodle paint

Application areas: water treatment mixing, solution preparation, suspension, rapid mixing, industrial heat transfer, etc.

Data parameters

Specifications and Models | Configuration parameters | Control method | |||

Volume (L) | Pump and tank configuration | Material | L然过m) | ||

Propeller, paddle, Hyperboloid mixer Submersible mixers, etc. | Rotational speed: 16-160 r/min Power: 0.03-5.5KW | Blade type: 2 leaves, 3 leaves | 316, 304 Carbon steel, rubber-lined steel Fiberglass | Blade diameter: φ200-500mm Pole length: 0.5-3m | Standard/Variable Frequency Explosion-proof/Outdoor Power supply: 220V/380V 50Hz |