- Home

- Products

- About Us

- Services & Support

- News

- Contact Us

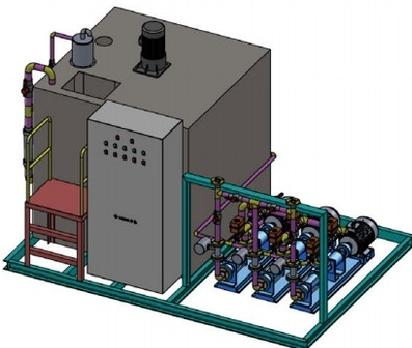

During the treatment of acidic wastewater in a water treatment system, pH is neutralized and adjusted. In the process of lime slurry addition, lime is often prepared and then added. This addition process requires high continuity, and manual addition is labor-intensive. To meet market needs, we are now offering lime slurry dosing devices to the environmental water treatment market. These devices feature simple operation, continuous addition, and stable dosage. Lime (powder) dosing equipment is a device for storing, preparing, and adding quicklime powder. The lime silo, along with a quantitative feeding system, self-unloading sealed tank trucks, lime slurry mixing tanks, and lime slurry delivery pumps, forms a complete limestone powder silo system.

During the treatment of acidic wastewater in a water treatment system, pH is neutralized and adjusted. In the process of lime slurry addition, lime is often prepared and then added. This addition process requires high continuity, and manual addition is labor-intensive. To meet market needs, we are now offering lime slurry dosing devices to the environmental water treatment market. These devices feature simple operation, continuous addition, and stable dosage. Lime (powder) dosing equipment is a device for storing, preparing, and adding quicklime powder. The lime silo, along with a quantitative feeding system, self-unloading sealed tank trucks, lime slurry mixing tanks, and lime slurry delivery pumps, forms a complete limestone powder silo system.

Working principle:

Lime powder is stored in a lime silo and fed evenly to a feeder. A screw conveyor feeder sends the lime powder into a dissolving tank for dissolution. The dissolving tank agitator thoroughly mixes the solution. The prepared solution is then pumped to the user by a lime slurry pump.

Features:

1. Basic loading and unloading capacity: Powder silo storage capacity ranges from 5 m³ to 500 m³; lime powder preparation capacity ranges from 5 to 10,000 kg/h; lime slurry (lime milk) preparation capacity ranges from 100 to 100,000 kg/h. (Concentration 10%)

2. Continuous preparation: The star feeder for powder is equipped with a speed control device, which allows for a wide range of feed rate adjustment and high accuracy in lime slurry concentration preparation.

3. Advanced vibrators or arch breakers can be selected to make lime feeding smoother.

4. The solution tank stirring device allows for the adjustment of the ratio between the feed rate and the water rate, resulting in more complete digestion of quicklime and higher digestion efficiency.

4. The solution tank stirring device allows for the adjustment of the ratio between the feed rate and the water rate, resulting in more complete digestion of quicklime and higher digestion efficiency.

5. The valves in the lime pipeline are made of 304 stainless steel, which is non-clogging, leak-free, and easy to operate and control, especially suitable for process conveying materials containing granules.

6. The level gauge uses a magnetic float level measuring instrument for precise control.

7. The electrical control system adopts an advanced control system, ensuring efficient equipment operation and reserving remote control terminals.