- Home

- Products

- About Us

- Services & Support

- News

- Contact Us

loading

Process Principle

The working principle of corrosion inhibitor (scale inhibitor) dosing device: During natural operation, industrial circulating cooling systems are prone to scaling or corrosion due to the combined effects of factors such as hardness, alkalinity, pH value, concentration ratio, temperature, and ambient humidity. Both negatively impact the safety and operational efficiency of the circulating cooling system. To inhibit scaling or corrosion, corrosion inhibitors or scale inhibitors need to be artificially added to the water. Commonly used corrosion inhibitors and scale inhibitors include polyphosphates, zinc salts, polycarboxylate salts, and phosphonates , etc.

Process Overview

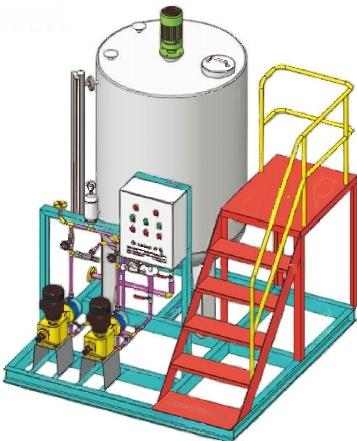

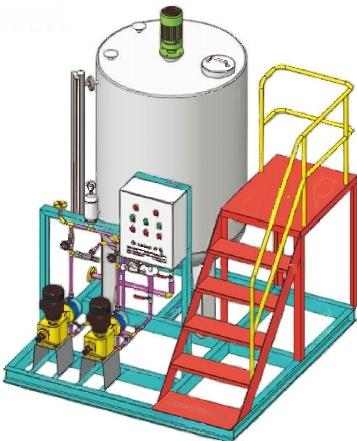

This device mainly consists of four parts: a drug solution preparation system, a metering and dosing system, a safety system, and a control system.

. Dosing control can be manual or automatic, based on control signals output from a higher-level system.

Application areas

Cooling circulating water treatment for thermal power generation or petrochemical plants

Data parameters

Data parameters

Specifications and Models | Configuration parameters | Control method | ||||

Volume (L) | Pump and tank configuration | Material | External dimensions L×W×H (mm) | |||

CTD-1□□/1□□ | 30-20000 | 1 barrel 1 pump | 304, PP, PE Carbon steel, rubber-lined steel UPVC | Minimum: 350×350×400 Maximum: 3150×3150×335 0 | 0 0 | Manual button/automatic instrument control /PLC Touch Control/DCS Remote Control /GPRS wireless/Special requirements Seeking (explosion-proof, frequency conversion, heating and insulation, etc.). |

CTO-1□□/2□□ | 1 barrel 2 pumps | Minimum: 350×350×400 Maximum: 3150×3150×335 | ||||

CTD-2□□/1□□ | 2 barrels and 1 pump | Minimum: 700×500×400 Maximum: 6900×3500×335 | ||||

CTD-2□□/2□□ | 2 barrels 2 pumps | Minimum: 700×500×400 Maximum: 6900×3500×3 | ||||

350 power supply: 220V/380V 50Hz | ||||||

CTD-2□□/3□□ | 2 barrels 3 pumps | Minimum: 700×500×400 Maximum : 6900×3500×335 0 | ||||