- Home

- Products

- About Us

- Services & Support

- News

- Contact Us

loading

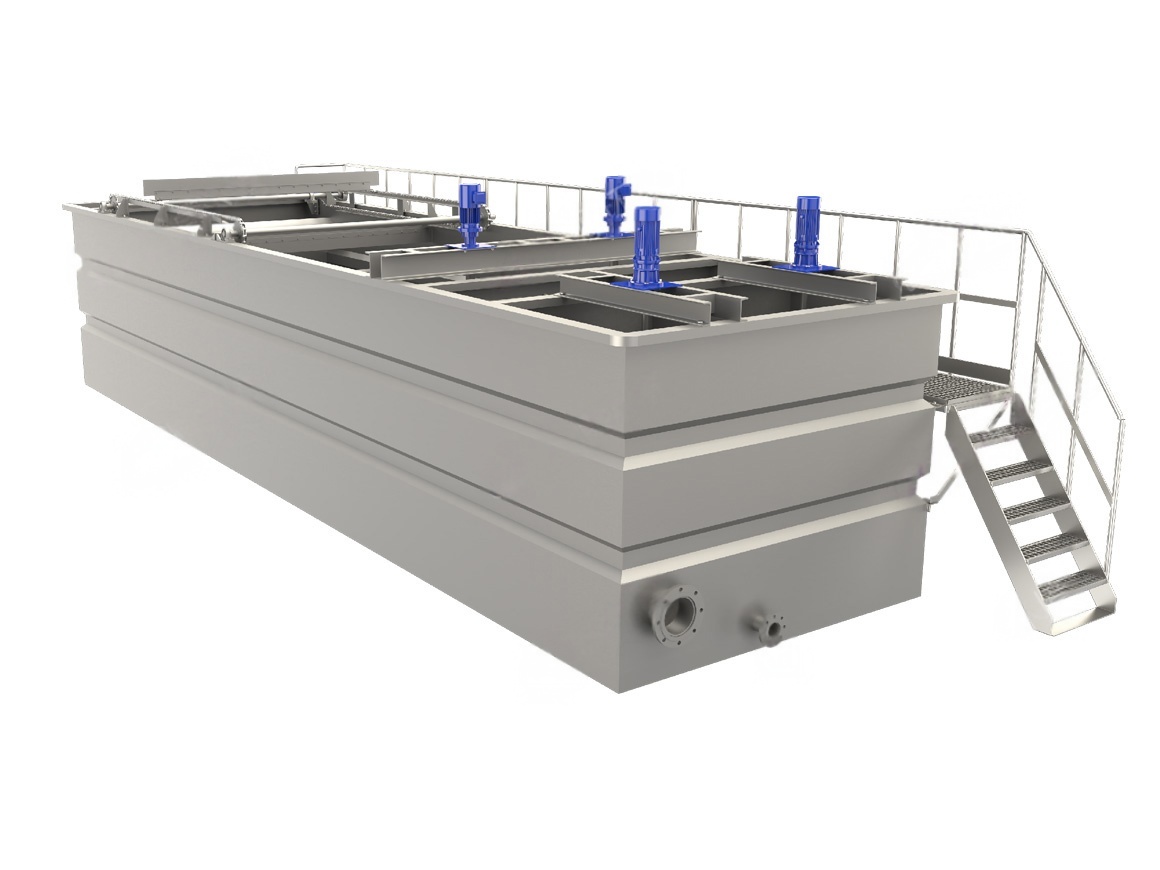

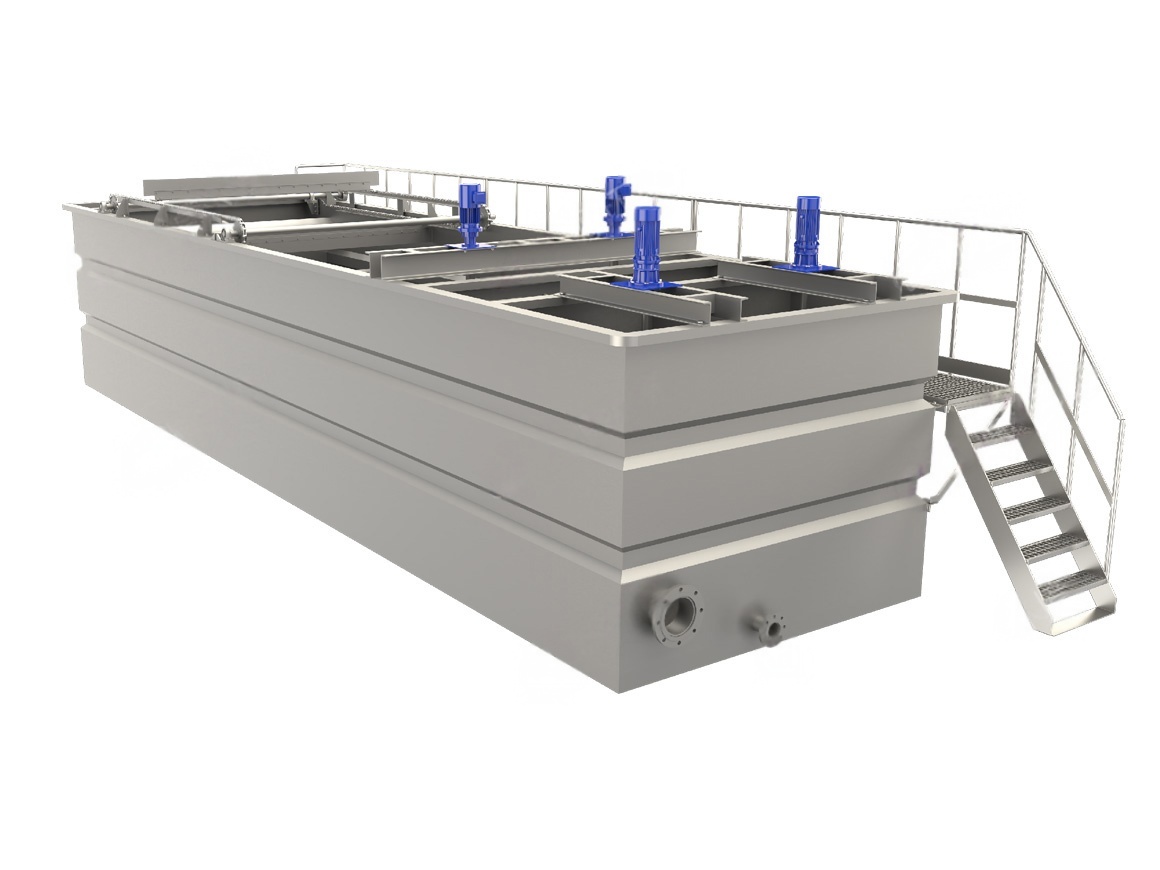

Vortex-induced air flotation

Advantages

● No need for circulating pumps, air compressors, or pressure vessels

● Saves on operating costs and floor space, reducing investment costs

● Simple, compact, and maintenance-free

● Particularly suitable for oily wastewater treatment

Applications

● Oily wastewater pretreatment

● Oily wastewater treatment in the petrochemical processing industry

● Oily wastewater and reinjection water in the oil extraction industry

● Slaughterhouse wastewater treatment in the meat processing industry

● Oily wastewater treatment in the dairy processing industry

● White water treatment in the pulp and paper manufacturing industry

● Oily wastewater treatment in the machining industry

Principle: The vortex-type dissolved air flotation (DAF) system consists of an aerator, a flotation tank, a sludge scraper, and an electrical control box. The aerator generates bubbles by drawing in air at high speed through a high-speed rotating motor. These microbubbles are then evenly distributed throughout the wastewater by a stainless steel diffuser impeller.

The aerator utilizes the centrifugal force created by the high-speed rotation of the drive impeller, generating negative pressure around it. This forces air or other gases above the water surface into the aeration inlets, which are then released from the submerged aeration outlets. When bubbles are generated in the small holes of the diffuser impeller, the high-speed rotating impeller cuts them into tiny bubble fragments with a diameter of 30-100 micrometers.

The flocculated wastewater enters the flotation tank and mixes with these microbubbles, carrying suspended solids to the surface. During this process, the microbubbles attach to the suspended solids. Once at the surface, the solids are supported by these bubbles and held in place. The scum formed on the surface is then scraped into a scum trough by the scum scraper.

Model number | Processing capacity (m³/h) | Dimensions : L×B×H (m) | Aerator (kW) | Slag scraper (kW) | Total power (kW) |

GWAF-1 | 1 | 1.4 × 0.55 × 1.1 | 0.37 | 0.18 | 0.55 |

GWAF-3 | 3 | 2.5 × 0.8 × 1.3 | 1.5 | 0.2 | 1.7 |

GWAF-5 | 5 | 2.5×1×1.3 | 1.5 | 0.2 | 1.7 |

GWAF-10 | 10 | 3×1.2×1.3 | 1.5 | 0.2 | 1.7 |

GWAF-15 | 15 | 4×1.2×1.3 | 2.2 | 0.4 | 2.6 |

GWAF-20 | 20 | 5 × 1.2 × 1.3 | 2.2 | 0.4 | 2.6 |

GWAF-30 | 30 | 5×1.6×1.8 | 2.2 | 0.4 | 2.6 |

GWAF-40 | 40 | 6×1.6×1.8 | 2.2 | 0.4 | 2.6 |

GWAF-50 | 50 | 6×1.8×1.8 | 4.4 | 0.4 | 4.8 |

GWAF-75 | 75 | 7×2.4×1.8 | 4.4 | 0.4 | 4.8 |

GWAF-100 | 100 | 8×2.4×1.8 | 4.4 | 0.4 | 4.8 |

GWAF-150 | 150 | 11.5 × 2.4 × 1.8 | 6 | 0.4 | 6.4 |

GWAF-200 | 200 | 15×2.4×1.8 | 9 | 0.4 | 9.4 |

GWAF-300 | 300 | 15×3.1×1.8 | 12 | 0.4 | 12.4 |

GWAF-400 | 400 | 17×3.6×1.8 | 12 | 0.4 | 12.4 |